Effective material handling equipment for warehouse management

To expand your fulfilment strategy, you may need to outsource some of these services with the help of a material handling company. Keeping the goods away on the same day reduces errors, loses the space needed for the warehouse, and reduces the risk of damage or theft. It also speeds up order fulfilment, as items in the peak rack are already ready for retrieval. The direct put-away system, the process of disposing of goods on the same day, relies on advanced warehouse inventory management system. Here's what you need to know about third party logistics using material handling equipment and unleashing its prowess.

Material handling offer many advantages over traditional barcodes. Material handling does not require a line of sight such as a barcode, limiting the amount of material control. In addition, Material handling can select an inventory presence of up to 40 feet for a fixed reader, 20 feet for a handheld reader, and more than 100 feet for an active system.

Material handling empower warehouses to collect more data about their operations, creating a platform for further insights into content management improvements.3PL providers provide similar services to accomplished companies including warehousing, inventory management, shipping, picking and packing, FLT and LTL, contrast logistics and kitting and customization.

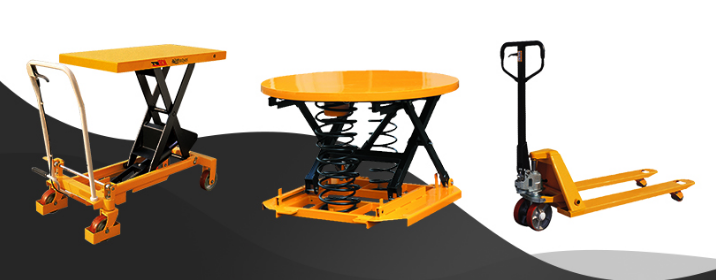

Working with a high quality 3PL firm can help you achieve diverse, successful results at the end of your company's warehousing and fulfilments. Various 3PL services provide specialized services such as cold filling, storage and shipping of hazardous materials, or the management of heavy, heavy and high value products warehousing. View products by visiting www.equip2go.com.au.